Table Of Contents

Signs a Cylinder Needs Immediate Inspection

Certain indicators signal that a cylinder requires immediate inspection. Visible wear and tear, such as dents, scratches, or rust, can compromise the cylinder's integrity. Additionally, unusual noises during operation may suggest underlying issues that need attention. Any signs of leakage or moisture accumulation around the cylinder are also urgent warnings, as they may lead to further damage or dangerous situations.

Routine Hot Water System Inspections help to identify these issues early. Professionals examine the entire system, focusing on components that may be prone to failure. A thorough check allows for the prompt addressing of potential hazards, minimizing risks to both the system and the users. Regular oversight is crucial for maintaining safety and efficiency in hot water systems.

Identifying Visible Damage

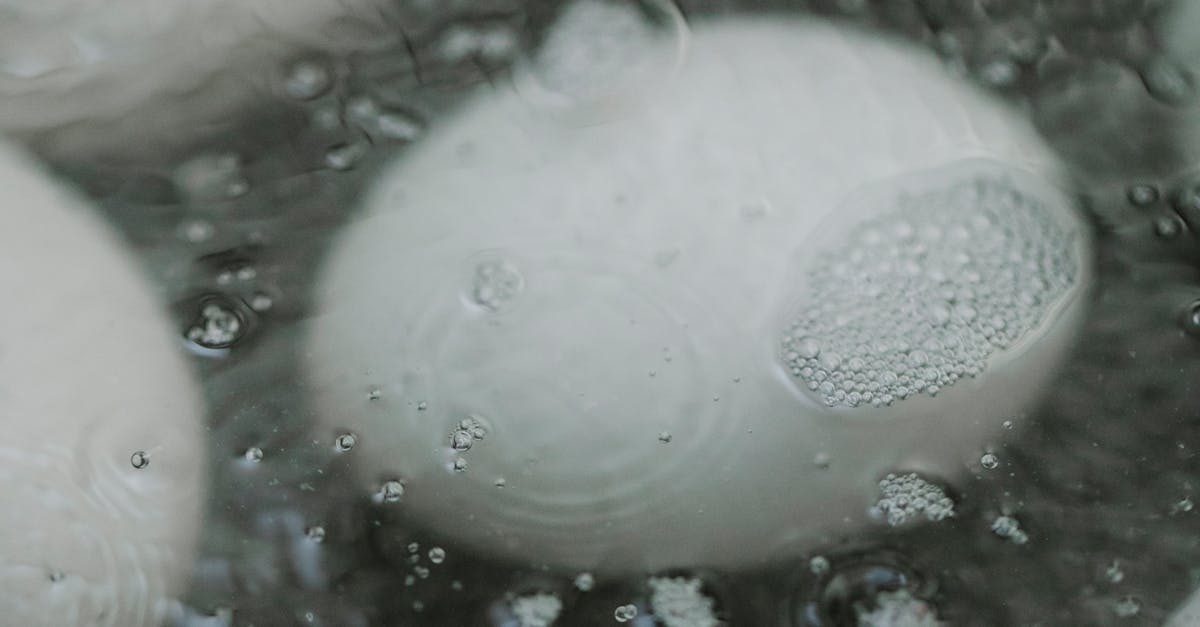

Visible damage on a cylinder can manifest in various forms, often signaling the need for immediate attention. Look for signs such as rust, dents, or corrosion on the outer surface. Any noticeable leaks or bulges may indicate structural failure. Regular Hot Water System Inspections can help identify these issues early on, preventing potential hazards.

Another critical aspect to consider is the condition of the fittings and connectors. Frayed or damaged hoses can lead to significant safety risks. Inspect rubber seals and valves for cracks or wear, which might compromise the system's integrity. Addressing these visible damages promptly can extend the life of the cylinder and maintain its safe operation.

The Inspection Process

The inspection process for cylinders involves a detailed examination that ensures they function safely and efficiently. Inspectors start by checking for any external signs of wear or damage, which may indicate potential issues. Visual assessments are crucial, as they provide insights into the general condition of the cylinder. Regular Hot Water System Inspections can help catch problems early, reducing the risk of malfunction.

Following the visual assessment, inspectors often conduct functional tests. These tests may include pressure checks and evaluating the integrity of the fittings. The goal is to guarantee that the cylinder operates within the safety guidelines established by relevant regulations. Thorough documentation of each inspection is vital, as it helps track the cylinder's history and supports any necessary repairs or maintenance actions.

Steps Involved in a Thorough Check

The inspection process begins with a visual examination of the entire cylinder. Inspectors look for any signs of rust, corrosion, or leaks around the vessel and its connections. They check the integrity of the valve and any attached fittings to ensure they are secure and functioning correctly. Particular attention is paid to the pressure relief valve, which plays a crucial role in preventing excessive pressure buildup. If any visible damage is identified, it may indicate deeper issues that require immediate attention.

Next, the inspector will conduct functional testing to assess the efficiency and safety of the hot water system. This includes checking the temperature settings and operational pressures. Calibration of the system ensures it meets the required standards. The inspector also records any anomalies or irregularities found during the inspection. Comprehensive documentation is essential for tracking the condition of the cylinder over time and planning future maintenance or repairs. Hot Water System Inspections are vital not only for compliance but also for ensuring the safety and longevity of the system.

Common Issues Discovered During Inspections

During inspections, several common issues can arise that may jeopardize the functionality and safety of a cylinder. Corrosion is a frequent problem, often caused by prolonged exposure to moisture. This degradation can lead to leaks and ultimately compromise the integrity of the system. Inspectors often look for signs of wear on seals and gaskets as well, which may result in pressure fluctuations and inefficiency in performance.

Another concern is sediment buildup inside the tank. Over time, minerals and other debris can accumulate, leading to reduced heating efficiency and potential overheating. Proper Hot Water System Inspections involve checking for this buildup and assessing any potential blockages that could impact performance. Ensuring that these issues are identified early helps maintain system reliability and extend the lifespan of the equipment.

Potential Risks and Repairs

Neglecting regular inspections of cylinders can lead to significant risks, particularly concerning safety and efficiency. One common issue that may arise is the presence of corrosion, which weakens the structural integrity of the cylinder. If left unchecked, this deterioration can result in catastrophic failures, including leaks or even explosions. Hot Water System Inspections are crucial in identifying such vulnerabilities early, ensuring that any signs of wear or damage are addressed before they escalate into serious problems.

Repairs following an inspection can vary widely depending on the extent of the damage found. Minor issues, such as fittings that need tightening or small leaks, might require only basic maintenance. More severe problems could necessitate complete cylinder replacement or extensive repairs, which can be costly and time-consuming. Regular Hot Water System Inspections not only help in discovering these issues but also assist in planning the necessary repairs efficiently, ultimately extending the lifespan of the system.

FAQS

How often should a cylinder be inspected?

Cylinders should be inspected at least once a year, but more frequent inspections may be necessary depending on usage, environment, and specific regulations applicable to the type of cylinder.

What signs indicate that a cylinder needs immediate inspection?

Signs that a cylinder needs immediate inspection include visible damage such as dents, rust, leaks, or unusual pressure readings, as well as any signs of corrosion or wear.

Who is qualified to perform cylinder inspections?

Cylinder inspections should be performed by certified professionals who are trained in handling and assessing the specific type of cylinder in question, including adherence to safety regulations.

What are the common issues found during a cylinder inspection?

Common issues discovered during inspections include leaks, corrosion, valve malfunctions, pressure issues, and physical damage to the cylinder body.

Are there specific regulations governing cylinder inspections?

Yes, there are various regulations governing cylinder inspections, which can vary by industry and location. It is important to consult local safety and regulatory guidelines to ensure compliance.